Hand-hammered canister, Shikinshoku Tsuiki Copperware. Traditionally joined tea canister with an outer and inner lid that is lined with either silver or tin to preserve the tea’s longevity and taste.

Image courtesy of: Tea Dealers

Gyokusendo was founded in 1816 by a master craftsman who wanted to create copper-ware by hammering and shaping a single sheet of copper into a finished item. Best of all, the reason behind the company’s founding is fascinating. The Edo Period (1603-1868) was a time when the Shinano River would flood Tsubame-Sanjo every three years. As such, agriculture was constantly ruined and the local population was repeatedly left without a chance at commerce.

Understanding the troubles, the area’s governor sent a blacksmith from Edo (present-day Tokyo) to teach the local farmers how to make Japanese nails. Over time, what began as a side business during hard times became the area’s main source of income. These metalworking techniques turned the region into a place “built by the hammer.” That, along with the move of Toshichi, an artisan who moved to the area, brought about the hammering technique that is called tsuiki. The technique was eventually passed down to Kakubei Tamagawa and before long, he and his apprentices were known as makers of household items such as pots, kettles, and wash-bins.

Sake Cup (E50-0101), blue dots on light silver.

Image courtesy of: Gyokusendo

In 1868, the Japanese government sought to bring international publicity to the country’s artisan industries in order to promote exportation. As a result, the companies that had previously been making only simple household items began creating pieces that showcased their unique aesthetics and craftsmanship. Gyokusendo was one of the first workshops to make their international debut.

Local producers began submitting their works to exhibitions all over the world; Gyokusendo was selected to represent Japan in metal work. Local Japanese engravers were vital to adding new ideas to the company. However as artisans aged, the need to teach a new group of artisans became clear. Over time, as more and more Kakubei family members remained at the company’s helm, a branch opened in Yokohama; this helped to encourage the growth of hand-hammered copper ware in the region. Currently, Masao Tamagawa, the Sixth Generation Head, works alongside other artisans to keep alive the magic of the past 160 years and six generations.

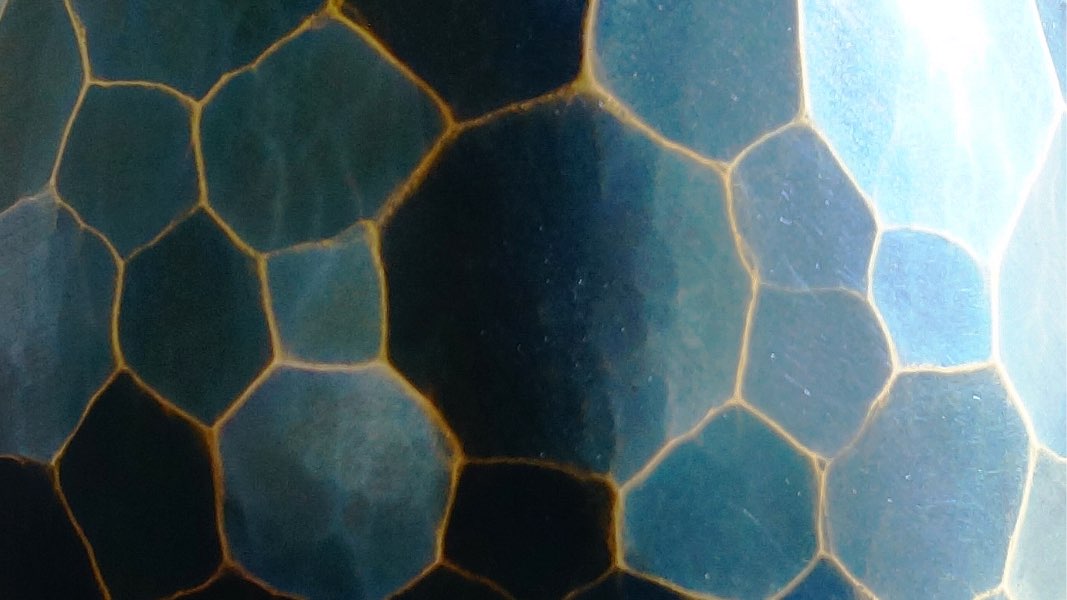

An up-close example of hammered copper.

Image courtesy of: Gyokusendo

Tsuiki is a metal-working technique that comes from the words “hammer” and “raise.” Using a variety of different tools, Gyokusendo’s artisans hammer to shrink the copper. Contrary to popular belief, hammering does not stretch the copper. The studio’s walls and cupboards are choke-full of mallets and hammers of all different shapes and sizes. However ultimately, it is up to the individual artisan to decide what tool to use based on what he plans to make.

Prior to coming into contact with a hammer, the copper sheets’ edges are lifted by “sinking” a large base using a mallet. The pounding causes wrinkles to form around the edges… the artisan remains vigilant to ensure that none of the wrinkles overlap. The next step involves “annealing;” this allows the copper to become malleable. The form’s shape is a result of repeated hammering and annealing. Following the first “sinking,” the artisan uses different anvil stakes to “raise” the edges in order to create a vessel. At this point, a bit of tin is melted and spread thinly over the piece. The vessel is then “baked;” the temperature of the oven allows the artisan to create an array of different finishing colors. The artisans use their lifelong experience to recognize when a piece has baked enough. Finally, the vessel is engraved… decorations are chiseled onto the surface using a number of small, rounded tools.

Inside the showroom.

Visitors can make an appointment to tour the studio to watch the artisans working on their copper-ware. Guests are also invited to the tatami room where they can touch and hold the finished vessels.

Image courtesy of: Gyokusendo

The company’s products are produced in five different colors: red, brown, blue, silver, and blends. Red color is produced when the copper is oxidized to an orange-red color. The technique has been passed down for generations; originally this was done in China. Red remains the most traditional color. Brown is produced via natural oxidization methods; this brown shade is unique to copper. The iridescent blue shades occur when the vessel is plated with tin and baked at a high temperature, oxidized, polished, and oxidized again. Developed in the studio in the early 20th-century, this color is synonymous of copper-ware made in the Tsubame-Sanjo region. Silver is produced when the tin is softened by being baked at a low temperature. The silver shade is essentially a contrast in the color that comes from chilling the colored surface to reveal the undisturbed copper underneath. Finally, the color blends have continued to develop over the past one-hundred years. Artisans achieve specific blends by selectively baking tin into particular areas.

Craftsmen learn the coveted techniques over the course of twenty to thirty years.

Image courtesy of: Is Japan Cool?

The techniques used at Gyokusendo have been handed down for seven generations. In order to preserve the artistry, the company has been certified as an Intangible Cultural Heritage of Niigata Prefecture. In true wabi-sabi fashion, the two hundred plus year old company is a perfect representation of grace and beauty.

Perhaps Pen said it best, “Unlike the objects with planned obsolescence that surround us, the life force contained in Gyokusendo’s creations only increases with each stroke. As the gaze is absorbed by the warm reflections of the hammered copper of a cup, one can discern the infinite patience of the artisan, shaping traditional objects that are made to last.”