Design

Poterie Renault

A collection of Potierie Renault.

Image courtesy of: Milled

173 years ago in Argent-sur-Sauldre, France, Stanislas Renault opened a workshop. Five generations later, the Renault family was still handcrafting iconic stoneware just as it has since 1847.

Deep in the Loire Valley, this enigmatic source of French culinary pottery was originally on the grounds of a local castle. Production at the current site began in 1865 and each piece was formed from local grey clay and finished by hand. Until recently, some distinct pieces were still being formed entirely by hand.

Stoneware utensil jar.

Image courtesy of: Remodelista

The region possesses the two essential ingredients for pottery making… clay and wood… which is readily available. For over 170 years, Potereie Renault supplied restaurants, cafes, and hotels with special pottery.

Interestingly, these kitchen items have always been associated with French regional cuisine; although now, they are much cherished by many outside the industry. This unique salt-glazed stoneware is beloved by professionals for the intrinsic qualities that it possesses.

The vintage French stoneware mixing bowls comes in five sizes.

Image courtesy of: Food52

What is unique and cherished is that these pieces retain heat and cold for much longer periods that stainless steel. In addition they are quite heavy and much more stable than their steel counterparts.

Poterie Renault bowls are glazed inside and on the rim; but they are left bare and matte on the outside. They are beautiful and they can be used for an infinite number of uses.

Until recently, an old brick kiln was used for firing; recently though, pieces were produced in a more efficient electric kiln.

Image courtesy of: Flotsom + Fork

Salt-glaze pottery is stoneware with a glaze of glossy, translucent formed by throwing sea salt into the kiln during the higher temperature section of the firing process. Sodium from the salt interacts with silica in the clay body to form a glossy and glass-like coating of sodium silicate.

Hand-turners still man certain workstations and the manual work allowed Poterie Renault to fulfill orders of small quantities giving them the upmost flexibility. The company always strived to quickly fulfill orders with specific requirements; this design activity was integrated into the factory’s modeling workshop.

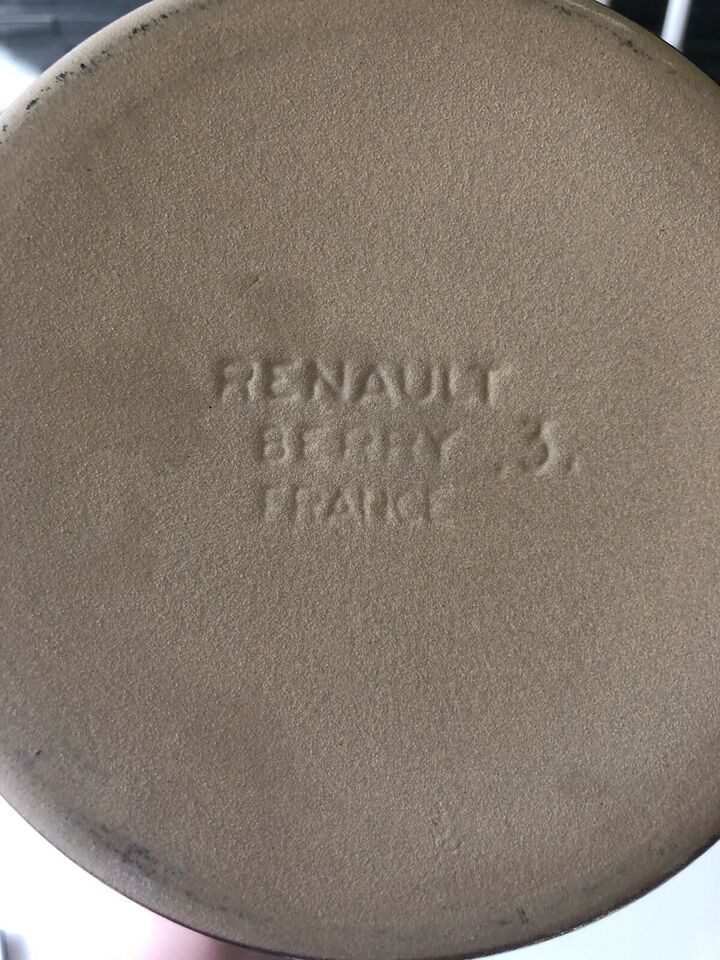

Marked on the bottom…

Image courtesy of: DBA

Sadly, the factory closed its doors in January 2016. Some pieces are still available through vendors who were smart enough to gobble up whatever pieces they found.

Pieces that are traditional yet can be used in both a microwave and conventional oven are scarce. Thus, it is important to remember all the history that precedes the company. RIP Poterie Renault.