Architecture

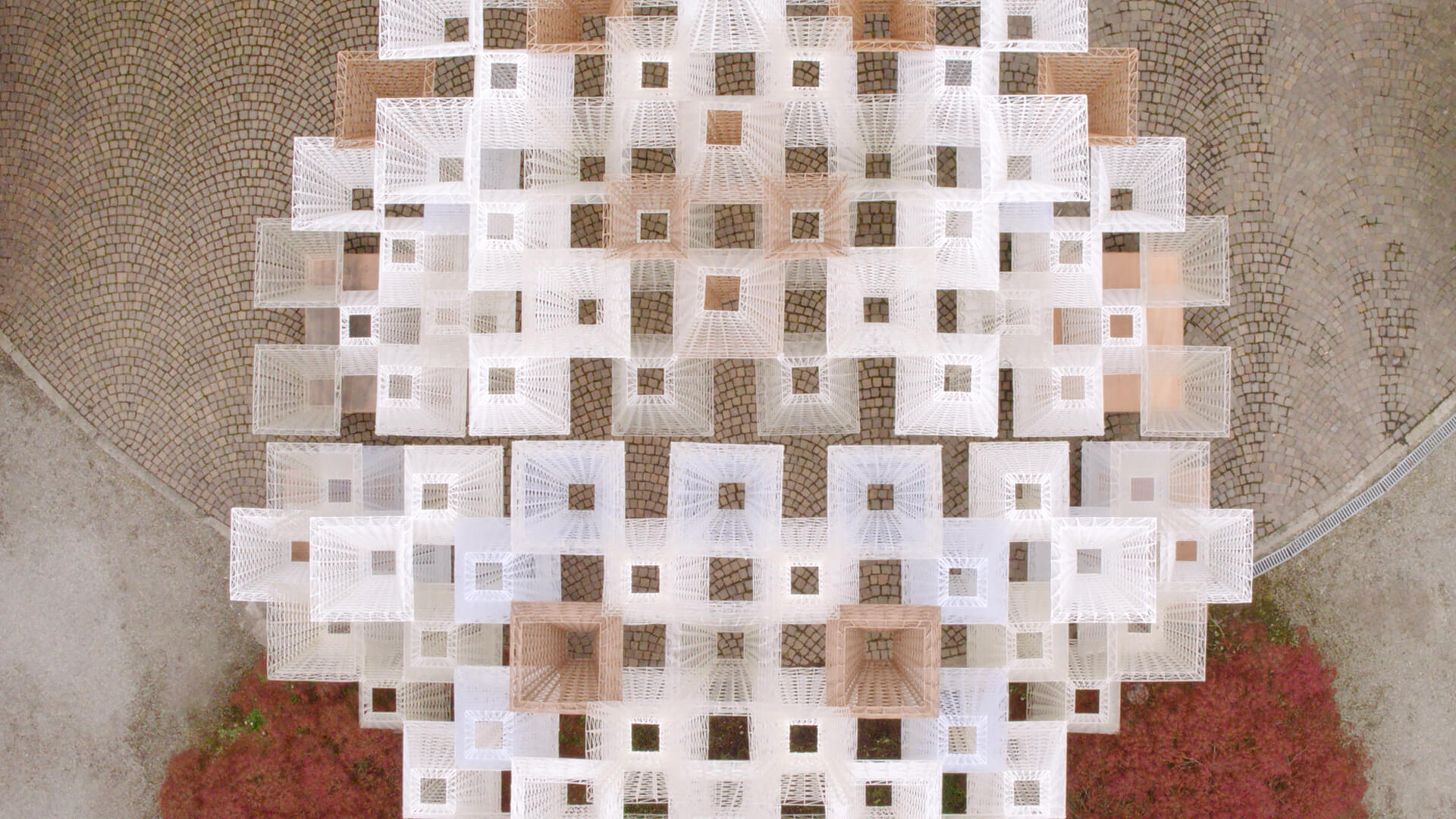

Innovative installation features bioplastic pyramids

More than 4,800 visitors saw “Conifera” on opening day.

Image courtesy of: Frame

For the eighth year in a row, the Swedish fashion brand COS has showcased an installation at the Milan Design Week. This year, 700 apex pyramids were laid out in the front gate and on the courtyard and garden of Milan’s Corso Monforte. The installation was designed by Arthur Mamou-Mani, the London-based architect perhaps best known for designing a twisting wooden temple for Burning Man last year.

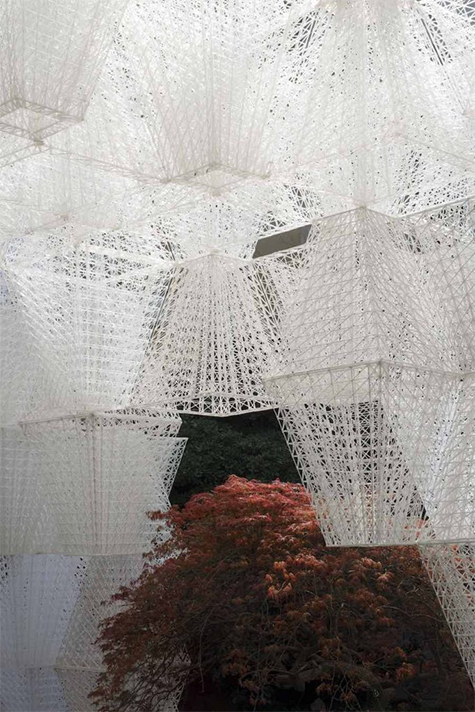

Titled “Conifera”, the pavilion’s modular and interlocking bio-bricks helped demonstrate the ways bioplastics in construction is both ideal and challenging.

This specific bioplastic is 100% compostable and made from a mixture of starch vinegar and Douglas fir.

Image courtesy of: Frame

One great aspect of Conifera was that the modular build allowed for quick dismantling and reconfiguring. Conifera was on the “drawing board” for a very long time. What made this installation possible was a specific printer and Mamou-Mani’s open-source software that creates parametric design. In essence, the right technology was available at the right moment and a perfect marriage was sealed.

While in action, the 3D printers used to fabricate each of the bricks, Dealt WASP, were available for visitors to observe. The main intent was for people to become curious about the options that are possible when using sustainable production techniques.

It took two months to print all of the bio-plastic bricks; four printers were employed between four and a half and seven hours a day. The unique lattice structure takes advantage of the materials’ strength; however, light still filters through the installation.

Image courtesy of: Dezeen

Something that both Mamou-Mani and Karin Gustafsson, COS’s creative director, were adamant about was that the environment’s needs were not ignored. Localization of production was extremely important.

Mamou-Main’s London office e-mailed the project’s code to 3D printing facilities near Milan. Minimizing shipping was a key component to moving forward. Furthermore, when thinking of the installation’s “life cycle”, a local composting factory needed to be on board. Ultimately, bio-plastic ends up back in the earth so finding a composting factory that was in agreement with the mutual concepts was vital.

The installation features three colors, the translucent bricks are PLA in it’s most basic form, the white bricks contain a pigment, and the brown hues are achieved by adding wood pulp to the mixture.

Image courtesy of: Archipanic

About this project, Mamou-Maini said, “Conifera blends the digital with the physical world while addressing sustainability through the use of compostable bio-plastic, produced and 3D printed locally. It is a dialogue between technology and craft, between the manmade and the nature and between monumentality and lightness. I hope the visitors will appreciate the futuristic high-tech aspect of the installation but also that is deeply poetic and human.”

Karin Gustafsson and Arthur Mamou-Mani stand in front of Conifera.

Image courtesy of: Mamou-Mani

Palazzo Isimbardi dates back to the 16th century. The juxtaposition between the centuries old city administration building and this forward-thinking structure is perhaps the most beautiful part of it all!