Design

Consigli knives

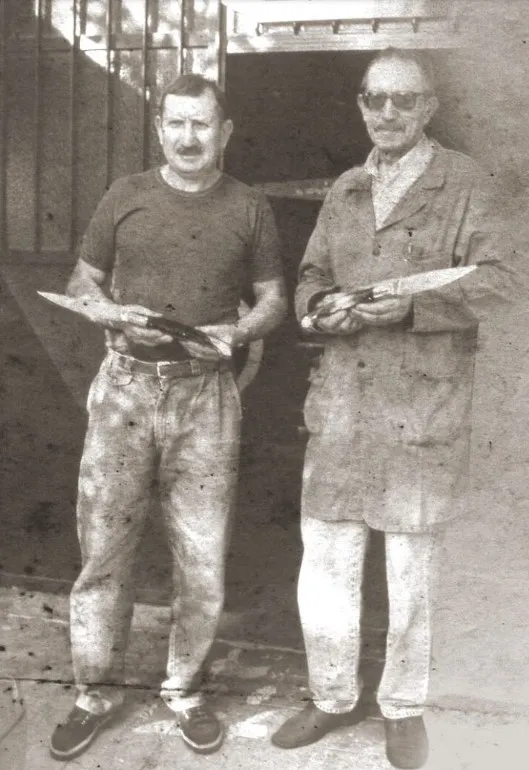

The Luigi and Enrico Consigli in Scarperia, Italy.

Image courtesy of: That’s Arte

Born and raised in Scarperia, the skilled craftsmen behind Consigili knives have been elevating this brand of knives to one of the top cutting tools companies in the industry. The brand’s hand-forged kitchen and table knives from Tuscany have been made in the same location since the Consigli brothers set up a workshop in the city of Scarperia following World War II.

Producing knives was in the brothers’ DNA… their father had been forging metal and making knives since the early part of the century. Unfortunately, once the Italian economy began to thrive, the population began to leave rural areas for the excitement and mystique of big cities. In such, handmade cutlery such as the knives the Consigli brothers produced, gave way to plastic and machine-made products.

An assortment of Consigli knives.

Image courtesy of: Food 52, photographed by: MJ Kroeger and Bobbi Lin

Regardless, the Consigli brother continued to produce high-quality knives. The pair began (courtesy of That’s Arte) “producing robust, practical knives with innovative materials and finishes. They did not change their production methods, though, trusting that their ancestors’ had already perfected them.”

Particularly, Consigli knives amassed a cult following in Sardinia where sheep breeding and rough-land toiling necessitated strong, heavy-duty blades. The brothers’ reputations as superior craftsmen quickly spread thanks to their products’ amazing quality and unparalleled aesthetics.

An Italian craftsman hand-hammering a knife… one part of the involved process.

Image courtesy of: That’s Arte

Today’s Consigli kitchen and table knives are made using the same methods the company’s founder used. Each item is made by skilled artisans using high-quality, raw materials and traditional production methods. High-end pieces include horn and olive wood handles where an intense manufacturing process is followed to ensure that each blade operates perfectly.

The undertaking starting from “from the blade cutting to its tempering, quenching, sharpening and polishing, requires the expertise and manual dexterity of master craftsmen who ensure that the performance of each blade is no less than perfect.”

An ox horn traditional Maremmano knife. The blade is made from hardened stainless steel and simple steel spring with embroidery.

Image courtesy of: Italian Deruta Pottery

The brothers, along with their friend Marcello Azzini began to produce under the name ConAz (a combination of the first parts of the trio’s first names). They became known for producing knives made from ABS, a fine resin with a special hardness, and unique gloss and toughness properties. Methacrylate resin was also used because it is known for its strength, durability, and abrasion resistance.

Switching a focus to producing practice knives and (courtesy of the company’s website) “prestige knives, such as the patted with polished horn and mirror-finish blade, achieved by mixing glue with fine emery.” Specifically, the polished horn was a telltale sign of utmost quality. In order to shape the horn, furnaces rather than paraffin were used. This unique method caused the layers to compact… a huge bonus as flaking was a common issue with knife handles. In addition, air tempering, where the blades were laid out on a cold floor, morphed into oil tempering. This more accurate and practical method became one of Consigli’s trademarks.

Consigli Roasting Set with cow horn, a two-piece set.

Image courtesy of: Fatto a Mano

These days, along with their traditional Italian models, Consigli also produces high-quality kitchen and table cutlery. Using high-end finishes such as buffalo horn and cow horn, authentic steel-working techniques remain at the center of the company’s ethos.

Currently, a second generation of Consigli’s are at the helm. The youngsters help Enrico following Luigi’s retirement. The family, still known as “Master Knife Makers” remains committed to “authentic steel-working techniques and to the preservation of the values of manual processing.” Furthermore, they remain forever “determined to meet the challenge of safeguarding the company’s artisanal traditions while remaining faithful to the ideals that lay behind the creation of ConAz in the Fondo Pasinetti, more than half a century before.”